Overview:

This article explains the Split, Drill Down and Flatten features and how to enable them.

Split Feature

The main reason to use this is if the quantity needed for an order is greater than the amount available. If you've produced 8 units of a product but there were 10 on order — you can split the order, ship the produced quantity, and produce the rest later on the split off Work Order.

Drill Down Feature

When you have a multi-level or nested Bill of Materials, you're going to want to create a chained set of Work Orders. These are to produce the main item by creating Work Orders for all the sub-assemblies in a chain. All the Work Orders that are part of the chain have the same reference number so that you can keep track. You can also go on the Work Order List and pull up just that reference number to see all the ones in that chain. It's easier to follow along that way.

Flatten Feature

Personally this is my favorite. If you have multi-level Bill of Materials, sometimes you want all the sub-assemblies and production steps all on ONE Work Order. This would list all the components of the entire top-level item as though it were a single Bill of Materials. For this to work, sub-assemblies must be checked as 'Phantom BOM' in the system.

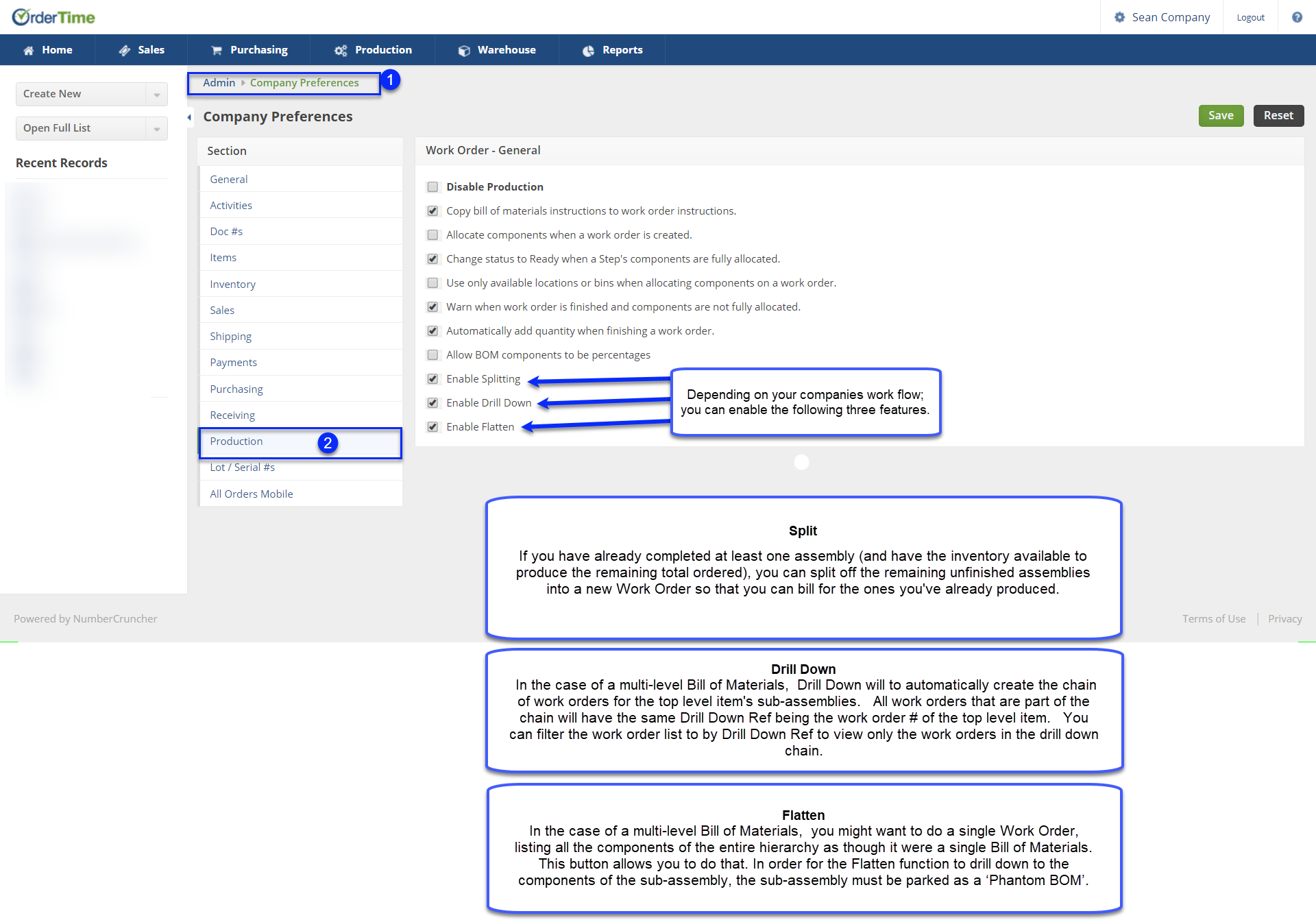

To Enable

To Enable these feature you will need to go into your company admin > Company Preferences > Production > check the boxes of the features you choose.