Overview

A production order is a strategic blueprint in the manufacturing process, designed to guide the creation of a finished product through a structured sequence of assemblies and disassemblies. This entails the use of multiple bills of materials (BOMs) and a series of work orders that detail each step's instructions and required components. The goal is to establish a logical and well-organized chain of events, ensuring the accurate transformation of raw materials into intermediate assemblies and, ultimately, the desired finished goods.

Example

In this example we are going to create a Production Order to produce a slab of soap from 3 components, then create a scented lemon grass slab of soap by combining the slab of soap created in the first work order (this is a sub-assembly) with some lemongrass scent extract, and finally disassembling the Lemon Glass Slab into 36 6oz Lemongrass Bars and 72 Travel sized Lemongrass bars. Here is a graphical representation of the process.

How to set up Production Orders in Order Time:

Create the component items: Coco Oil, Shea Butter, Lye, lemongrass extract, 6 oz Lemongrass bars and Travel sized lemongrass bars.

Create the assembly item: Slab of soap and its corresponding bill of materials (23 oz of Coco Oil, 12 oz of Shea butter and 5 oz of Lye)

(Please refer to units of measure and UoM sets to understand how to convert from Pounds to Ounces or 55 Gal Drums to Ounces, etc.)

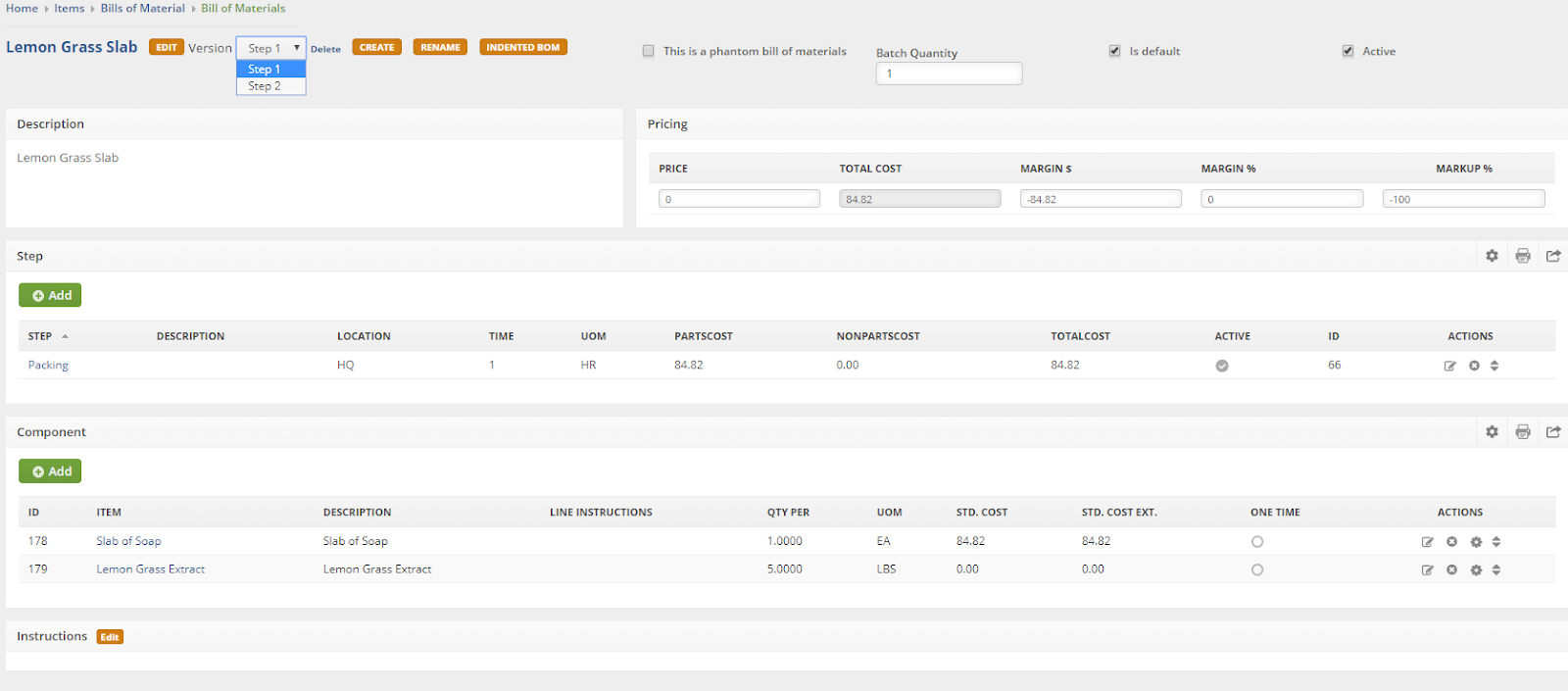

Create the assembly item: Lemon Grass Slab and its corresponding bill of materials (slab of soap and 25 Lbs lemongrass scent extract)

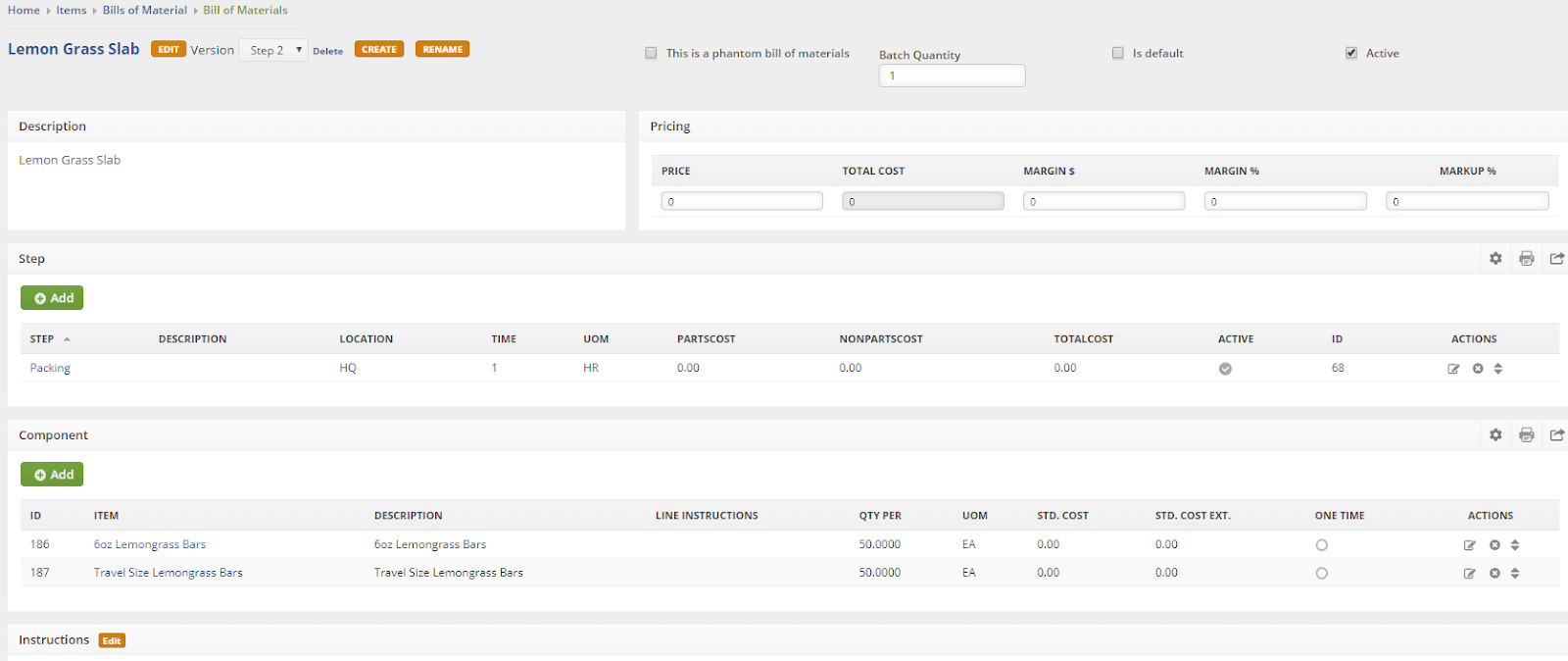

(The assembly item Lemon Grass Slab will have 2 BoM versions. One for the work order assembly and another for the disassembly into the finished component products.)

BOM Version “Step 1”

BOM Version “Step 2”

(Notice the difference in the components)

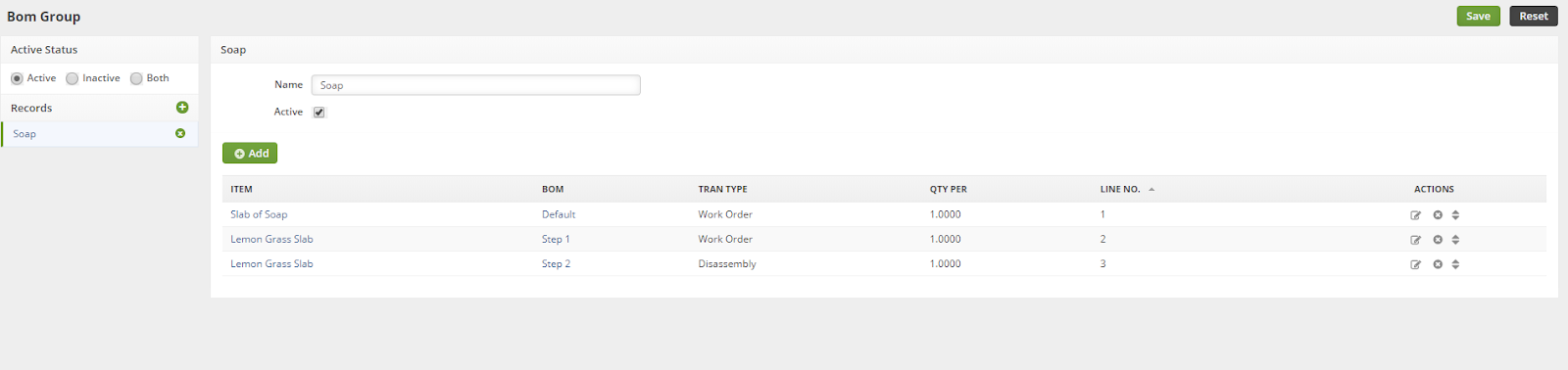

From the Admin/Profile Lists, create a BoM Group (I call this Soap). The BoM Group defines the actual sequence of work orders and/or disassemblies.

(Make sure that you enable the BOM Revisions and Production Orders in Company Preferences/Production)

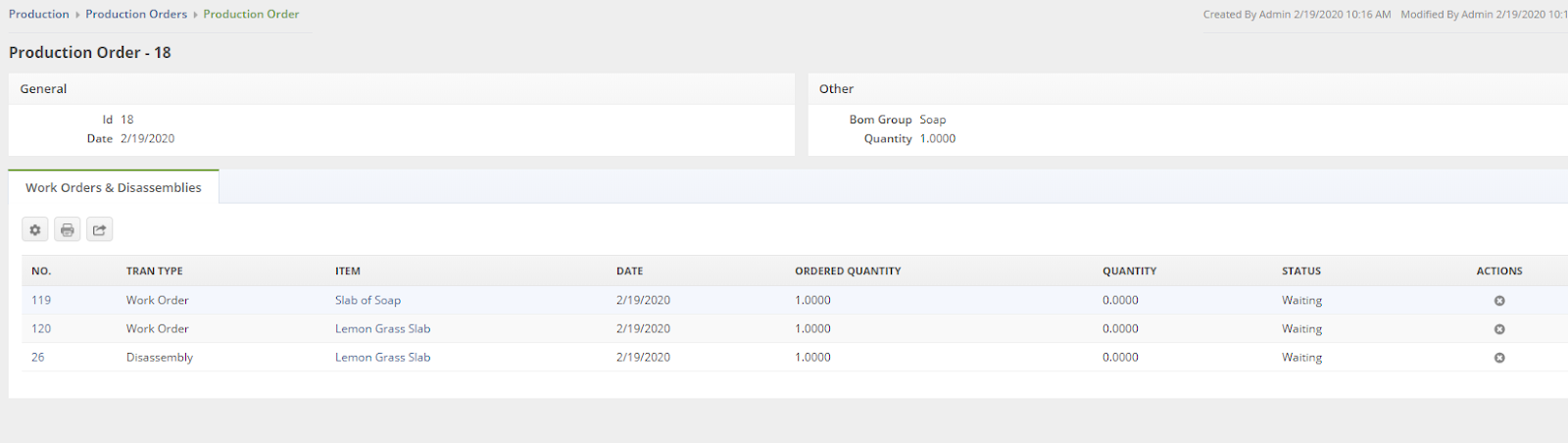

Create a new Production Order and select the BOM Group “Soap” from the pull down menu. Specify a quantity of 1 then click Save.

(You should now see the Production Order screen showing the work orders and/or disassemblies you created in the Soap BOM Group)

Click on the hyperlink for the first work order. Allocate and finish the work order.

Click on the hyperlink for the Next Work Order.

Allocate and finish the work order.

Click on the hyperlink for the next Disassembly.

Allocate and finish the disassembly.

(You will notice that the disassembly has the same assembly item, Lemon Grass Slab) however it uses the “step 2” version of the BoM.)

You have now successfully assembled the slab of soap, assembled the lemongrass slab and finally disassembled the lemongrass slab to the finished products…Congratulations!